- Home

- About Us

- Products

- Metal Stamping Parts Balance Clamp

- Metal Stamping Parts Magnet

- Metal Stamping Parts End Cover

- Metal Stamping Parts Motor

- Metal Stamping Parts Carbon Brush Holder Assembly

- Hardware Accessories

- Metal Stamping Balance Clamp

- Metal Stamping End Cap

- Metal Stamping Motor Case

- Metal Stamping Carbon Brush Holder Assembly

- Stamping Parts Hardware Accessories

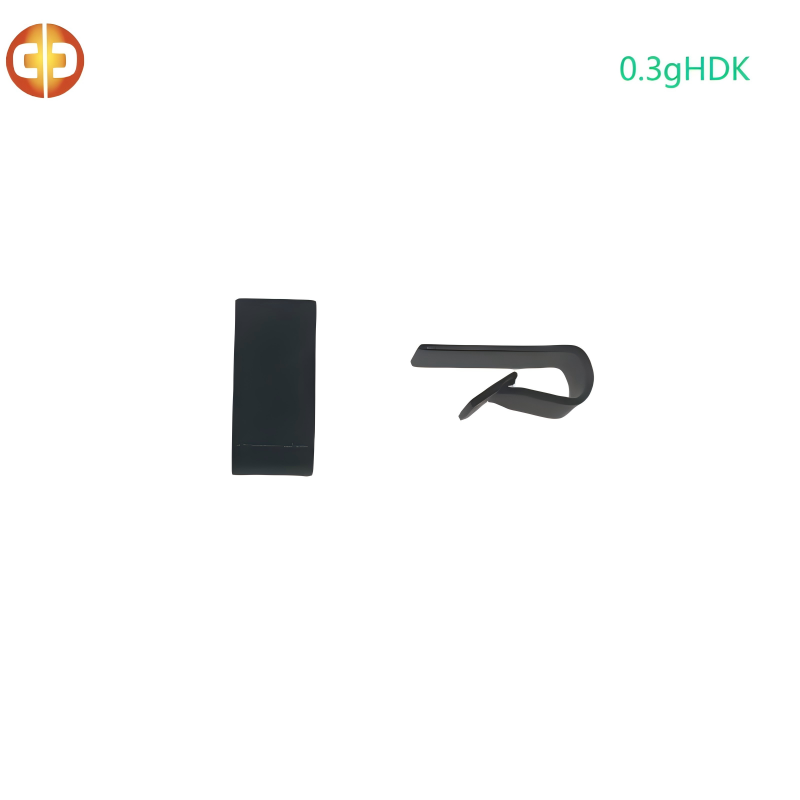

- Metal Stamping Parts Magnet Tile Clip

- News

- Download

- Send Inquiry

- Contact Us